Engineering

Development, Planning

CAD- supported projecting. Completion of complex tasks with our own construction department.

Feasibility analysis, value analysis, FEM- analysis.

- CNC- programming systems Coscom Profi CAM, Solid Mill and Index H200

- ERP system Infor with Edifact interface

- 3DCAD system Solid Works

- Interfaces: Step, IGS, dxf, dwg, Pro-E, SAT, stl, cgr

- Rapid Prototyping

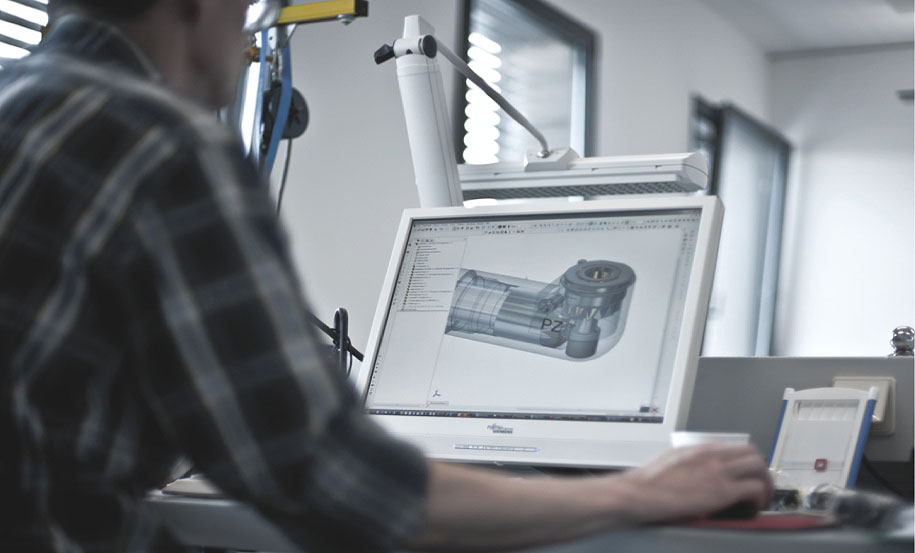

Turning

CNC- turning milling center

Over 50 CNC- turning milling center with up to 11 axes treat your complex work piece with all-round Turning ad milling options

- Off the rack up to Ø 90 mm

- In lining up to Ø 800 mm

- maximal turning length 1000 mm

- Hard turning to 65 HR

- Mirror face turning

- Inner groove milling with a roughness depth of Ra < 0,2

Milling

15 CNC- machining center

15 CNC- machining center, 3-, 4- and 5-axial provide an effective and efficient treatment.

- 5- axial simultaneously up to max. . x/y/z 850x700x500mm

- CNC- rotary table up to Ø 800 mm

- 8-way pallets milling centre with 180 tools x/y/z 630x630x560 mm

- High-frequency milling up to 45000 min-1

- Hard milling up to 65 HR

- Diamond milling < RZ 1µm

Grinding

Grinding, Lapping

The final polish of your components for optimal dimension- and contouring accuracies.

- Flat grinding x/y/z 1200x450x500 mm

- Round grinding up to Ø 350 mm

- Surface lapping

Product pictures

Wire Cutting

Wire Cutting, Tempering

For extremely small cutting widths of the work pieces, even with large-scale material thickness.

- 4 CNC- Wire cutting-machines, movement range x/y/z 630x400x160 mm

- 2 annealing furnaces 1350x1450x2000 mm (TxBxH), temperature max: 650° C

Honing

Surface Technology

Coated with highly decorative Eloxal

- Glass bead blasting

- Corundum blasting

- Stainless/steel cast blasting

- Sliding-surface grinding/ Polishing

- Dimensionally stable anodizing in IT6- quality – Blue staining

- Stainless steel passivating

Other Services

Labelling and Installing

The Assembling of your components and optical systems take place under cleanroom conditions of category ISO 14644-1:ISO category 5

- CNC- Laser marking machines x/y/z 600x400x300 mm

- CNC- engraving machines x/y/z 200x200x180 mm

Quality

Quality assurance

7 CNC- and 3 hand-operated measuring machines, 6 measuring microscopes

- Zeiss Accura VAST Gold scanning x/y/z 900x1200x700 mm

- Zeiss Prismo VAST scanning System x/y/z 900x2400x650 mm

- Zeiss Prismo VAST rotary table x/y/z

- Zeiss VISTA x/y/z 400x500x350 mm

- Zeiss C400 x/y/z 450x380x300 mm

- Mitutoyo Crysta Apex V9106 x/y/z 700x600x600 mm

- 5 measuring microscopes UWM digital with rotary table

- Calibration equipment BueCa/Calypso CAD-Offline Planner

- Roughness depth measuring machines/ Form testing machine

- Garant MM1 300 CNC 2x

- Garant MM1 300 1x